History

2020

POWERCASE - The large-area luminaire with unique case design

Market launch of the new large-area POWERCASE luminaire with a luminous flux of up to 83,500 lumens and unique case design.

2019

SONLUX invests in energy efficiency

SONLUX invests in a new, energy-efficient, all-electric injection moulding machine.

2018

GLADIATOR SL I & II

The latest generation of the tried-and-tested "power pack" GLADIATOR in two construction sizes with 4,000 lumens (SL I) and 8,000 lumens luminous flux (SL II) was successfully presented for the first time at the light+building trade fair in Frankfurt/Main in 2018.

2017

SONLUX honours anniversaries

In December 2017, employees were honoured for the first time for their 25 years of service to the company. All 18 employees have been with SONLUX since the company was founded.

2016

NEW LARGE AREA LIGHT POWERDISK

The first prototype of the new POWERDISK large area luminaire with a luminous flux of 50,000 lumens was presented at the light + building 2016. Series production starts in the same year.

2016

The name and corporate form of the company was changed from Sonlux Licht- und Elektroinstallation GmbH & Co. KG to SONLUX Lighting GmbH.

2016

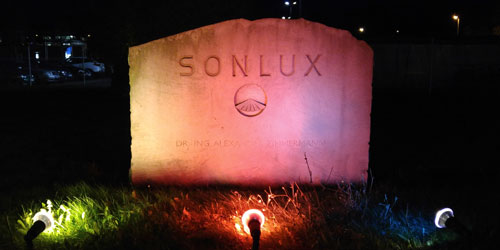

Dr.-Ing. Alexander Zimmermann, sole shareholder and managing director of SONLUX, celebrates his 70th birthday in May 2016.

2015

POWERTUBE WITH LED TECHNOLOGY

The further development of the POWERTUBE large area luminaire with state-of-the-art LED technology was presented in two different versions and will now be delivered with a transport bag.

2015

SONLUX starts a design study in cooperation with the University of Applied Sciences Magdeburg-Stendal, Faculty of Engineering / Industrial Design under the direction of Professor Kluge. The task for the students was to design a mobile accu LED work light.

2014

PROTECTIVE TUBE LIGHT LED

Following the market success of the first series of protective tube lights , the new protective tube lights series with highly efficient LED technology was successfully presented at the light + building 2014.

2013

Bamberg entrepreneur Dr.-Ing. Alexander Zimmermann receives honorary award

Dr.-Ing. Alexander Zimmermann, sole shareholder and managing director of RZB Rudolf Zimmermann, Bamberg GmbH and its sister company SONLUX Licht- und Elektroinstallation GmbH & Co. KG from Sondershausen/Thuringia received the honorary award of the town of Sondershausen on the occasion of the 20th anniversary of SONLUX.

2013

Completion of the multi-purpose hall (goods receiving) and the employee parking lot.

As a result of the investments, the existing SONLUX plant grew into one of the most advanced development and production facilities in the region with innovative manufacturing, automation and computer technologies.

2012

MARKET LAUNCH GLADIATOR III

One of the world's first exclusively for LED lamp technology developed mobile work light in a full plastic housing.

2011

DESIGN AWARDS FOR GLADIATOR II

Our GLADIATOR II proves, that function and design can be successfully combined into a single unit for portable work lights.

Design Awards:

iF Product Design Award 2010

reddot best of the best 2010

Design Award Germany 2011 SILVER

2010

SONLUX INSTALLS PHOTOVOLTAIC SYSTEM

Area with collectors: approx. 7 000 m2

Number of modules: 1062

Power: approx. 244 kilowatts

CO2 savings: approx. 200 000 kg/year

This corresponds to a supply of approx. 100 households

HONOR

Dr. -Ing. Alexander Zimmermann received the Investment Award 2010 in Thuringia and Bavaria for his commitment and dedication.

2009

GLADIATOR II

In the year of the global economic crisis, the second generation of the successful work lights series was launched on the market. Only a few months later, the product was awarded with several design prizes.

2008

SPARTACUS

Market launch of the SPARTACUS dome luminaire

2005

NEW PROTECTIVE TUBE LIGHTS

Market launch of the protective tube lights based on compact fluorescent lamps, combined with a first major order for the assembly stations of the world's largest passenger aircraft in Hamburg.

2005

Expansion of the product technology by commissioning a vacuum evaporation plant and a thermoforming plant for the production of plastic moulds.

2003

Expansion of the work lights series with the GLADIATOR mini 24 W.

Inauguration of the new SONLUX logistics centre.

2002

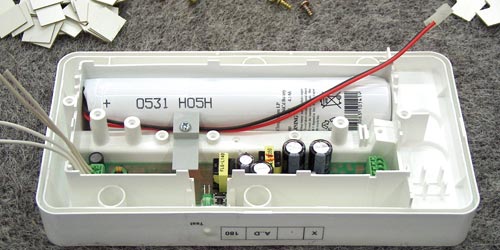

NEW PLASTIC INJECTION MOLDING MACHINE

Investment in a two-component plastic injection moulding machine for the efficient and high-quality production of housings of the GLADIATOR work lights series.

2000

PRODUCT PRESENTATION OF WORK LIGHTS SERIES GLADIATOR

After a successful product presentation at the light + building, the successful market launch of the GLADIATOR work lights series followed.

1998

ENTRY INTO THE MARKET FOR HIGH-QUALITY WORK LIGHTS

With the start of the development of the GLADIATOR 36 W and 72 W series of work lights, SONLUX lays the foundation for market entry in the field of high-quality mobile work lights for professional applications.

1997

BEGINNING OF THE FIRST OEM PRODUCTION

Following the successful market launch of the GSUN® 3 / GSUN® 4 emergency luminaires, the production was relocated from RZB Bamberg to SONLUX in Sondershausen. This was the beginning of the first OEM production for SONLUX.

1995

EXPANSION OF THE INJECTION MOLDING MACHINES AREA

In 1995, the rod and tube lights were converted based on thermoplastics. This further expanded the field of injection molding machines.

1994

STATE-OF-THE-ART ASSEMBLY LINE

Use of an high modern, automated assembly line for the production of oval and circular luminaires.

1993

CONVERSION & RENOVATION MEASURES

Shortly after the company was founded, extensive conversion and refurbishment measures began to prepare SONLUX for the future.

1992

FOUNDING OF THE COMPANY

Foundation of SONLUX GmbH & Co. KG by Dr. -Ing. Alexander Zimmermann.

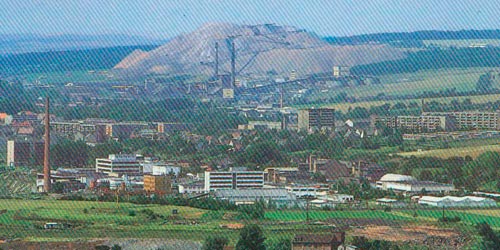

1991

STRATEGIC CONVERSION WORK

First strategic reconstruction measures to modernize the existing structure (e. g. dismantling of the 170 m high chimney stack of the former lignite-fired power plant).

1989

THE FALL OF THE BERLIN WALL

In the period of political turn-around, the former sub-states reunited. At the same time, VEB Elektroinstallation and RZB made initial efforts to further expand their cooperation.

1988

BEFORE THE GERMAN REUNIFICATION

VEB Elektroinstallation Sondershausen in Thuringia.

At that time, there were already cooperations with RZB Leuchten in Bamberg, which laid the foundation for the two companies to grow together.